How to Maintain the Engine Water Pump: Complete Guide for Longevity

🔧 Quick Water Pump Maintenance Checklist

| Maintenance Task | Frequency | Why It Matters | Industry Impact |

|---|---|---|---|

| Coolant Level Check | Monthly | Prevents dry pump operation | Overheating causes 15-20% of breakdowns |

| Coolant Replacement | Every 2-3 years | Prevents corrosion damage | Extends pump life significantly |

| Belt Tension Check | Every 10,000 miles | Ensures proper pump operation | Prevents 40% of premature failures |

| Leak Inspection | Monthly | Early problem detection | 30% of failures start with leaks |

Maintaining your engine water pump properly is absolutely essential for keeping your vehicle running smoothly. Furthermore, regular maintenance can save you thousands of dollars in costly repairs. In this comprehensive guide, we’ll show you exactly how to maintain your engine water pump like a professional mechanic.

Why Proper Maintenance of Engine Water Pumps Is Crucial

Your engine water pump works as the heart of your vehicle’s cooling system. Similarly to how your heart pumps blood, the water pump circulates coolant throughout the engine. Without proper maintenance, your engine can overheat and suffer serious damage.

“Engine overheating accounts for approximately 15-20% of vehicle breakdowns globally.” – AAA Foundation for Traffic Safety

Additionally, poor water pump maintenance leads to several expensive problems:

- Complete engine failure – costing $3,000 to $8,000 to replace

- Reduced vehicle lifespan – shortening your car’s life by years

- Emergency roadside breakdowns – leaving you stranded unexpectedly

- Higher fuel consumption – wasting money on gas

Therefore, investing time in water pump maintenance now saves you significant money later. Moreover, proper maintenance keeps your family safe on the road.

How to Check and Maintain Coolant Levels in Your Water Pump

Checking your coolant level is the most important step in water pump maintenance. First, always check coolant when the engine is completely cold. Hot coolant can cause serious burns.

Step-by-Step Coolant Level Check:

- Locate the coolant reservoir – usually a plastic tank near the radiator

- Check the level markings – look for “MIN” and “MAX” lines on the tank

- Ensure proper level – coolant should be between these marks

- Add coolant if needed – use only the manufacturer-recommended type

Importantly, never mix different types of coolant. Different coolants can react chemically and damage your system. Instead, always use the exact type specified in your owner’s manual.

For more detailed coolant specifications, visit the Society of Automotive Engineers (SAE) guidelines.

Detecting and Repairing Water Pump Leaks Early

Water pump leaks are serious warning signs that require immediate attention. Early detection prevents major engine damage and expensive repairs.

Common Signs of Water Pump Leaks:

- Coolant puddles – green, red, or orange liquid under your parked car

- Steam from engine – visible vapor coming from the engine bay

- Sweet smell – antifreeze has a distinctive sweet odor

- Low coolant warnings – dashboard lights indicating low coolant

“Industry data shows that 30% of water pump failures begin with seal leaks.” – Automotive Maintenance & Repair Journal

If you notice any leak symptoms, take action immediately. Small leaks quickly become major problems. Additionally, driving with a leaking water pump risks complete engine failure.

For professional leak detection techniques, consult resources from ASE (National Institute for Automotive Service Excellence).

The Importance of Regular Coolant Replacement

Coolant doesn’t last forever. Over time, it loses its protective properties and becomes acidic. Consequently, old coolant can actually damage your water pump and engine.

Why Coolant Degrades:

- Heat breakdown – constant high temperatures break down chemical bonds

- Contamination – debris and particles accumulate over time

- Chemical reactions – coolant reacts with metal components

- Additive depletion – protective additives get used up

Recommended replacement schedule: Every 2-3 years or 30,000-50,000 miles, depending on your vehicle. However, always check your owner’s manual for specific requirements.

Fresh coolant provides several benefits:

- Better heat transfer efficiency

- Improved corrosion protection

- Extended water pump life

- Reduced maintenance costs

How to Inspect and Adjust Water Pump Belt Tension

The water pump belt drives your water pump. Therefore, proper belt tension is crucial for efficient operation. Too loose, and the belt slips. Too tight, and it wears out bearings quickly.

Checking Belt Tension:

- Locate the water pump belt – usually the largest belt in the engine

- Press the belt midway – between two pulleys with moderate pressure

- Measure deflection – should move about ½ to ¾ inch

- Adjust if necessary – loosen tensioner and adjust

Moreover, inspect the belt for these warning signs:

- Cracks or fraying – indicates age and wear

- Glazing – shiny, smooth surface from slipping

- Missing chunks – pieces of rubber worn away

- Stretching – belt appears longer than normal

Industry guidelines recommend checking belt tension every 10,000 miles. Additionally, replace belts every 60,000 to 100,000 miles for preventive maintenance.

Recognizing and Addressing Unusual Water Pump Noises

Your water pump should run quietly. Strange noises often indicate internal problems that need immediate attention.

Common Water Pump Noises and Their Meanings:

| Noise Type | What It Means | Urgency Level | Action Required |

|---|---|---|---|

| Grinding | Bearing wear | High | Replace pump immediately |

| Squealing | Belt slippage | Medium | Adjust belt tension |

| Rattling | Loose impeller | High | Professional inspection needed |

| Whining | Low coolant or air bubbles | Medium | Check coolant level, bleed system |

“According to automotive service data, 25% of water pump replacements are due to bearing failure.” – Motor Service Industry Statistics

Never ignore unusual noises from your water pump area. Early intervention saves money and prevents roadside breakdowns.

Industry Standards and Best Practices for Water Pump Maintenance

Following professional standards ensures your water pump maintenance meets industry requirements. These standards come from years of automotive engineering experience.

Key Industry Standards:

- SAE International guidelines – for coolant specifications and testing

- OEM recommendations – manufacturer-specific maintenance schedules

- ASE certification standards – professional technician requirements

- ISO quality standards – international automotive quality benchmarks

Best practices include:

- Use quality parts – invest in reliable replacement components

- Follow maintenance schedules – don’t skip recommended services

- Keep detailed records – track all maintenance activities

- Address problems early – don’t wait for complete failure

For comprehensive maintenance standards, reference the Motor Age professional automotive resource center.

Common Water Pump Problems and How to Prevent Them

Understanding common water pump problems helps you prevent expensive repairs. Most issues develop gradually and show warning signs first.

Top Water Pump Problems:

1. Seal Leaks (30% of failures)

Prevention: Regular coolant changes, avoid overheating, use proper coolant mixture

2. Bearing Failure (25% of failures)

Prevention: Proper belt tension, regular lubrication, avoid running dry

3. Impeller Corrosion

Prevention: Use correct coolant type, maintain proper pH levels, flush system regularly

4. Belt Wear and Slippage

Prevention: Regular tension checks, replace worn belts, keep pulleys clean

Research shows that preventive maintenance reduces breakdown risk by up to 40%. Therefore, investing in regular maintenance saves significant money over time.

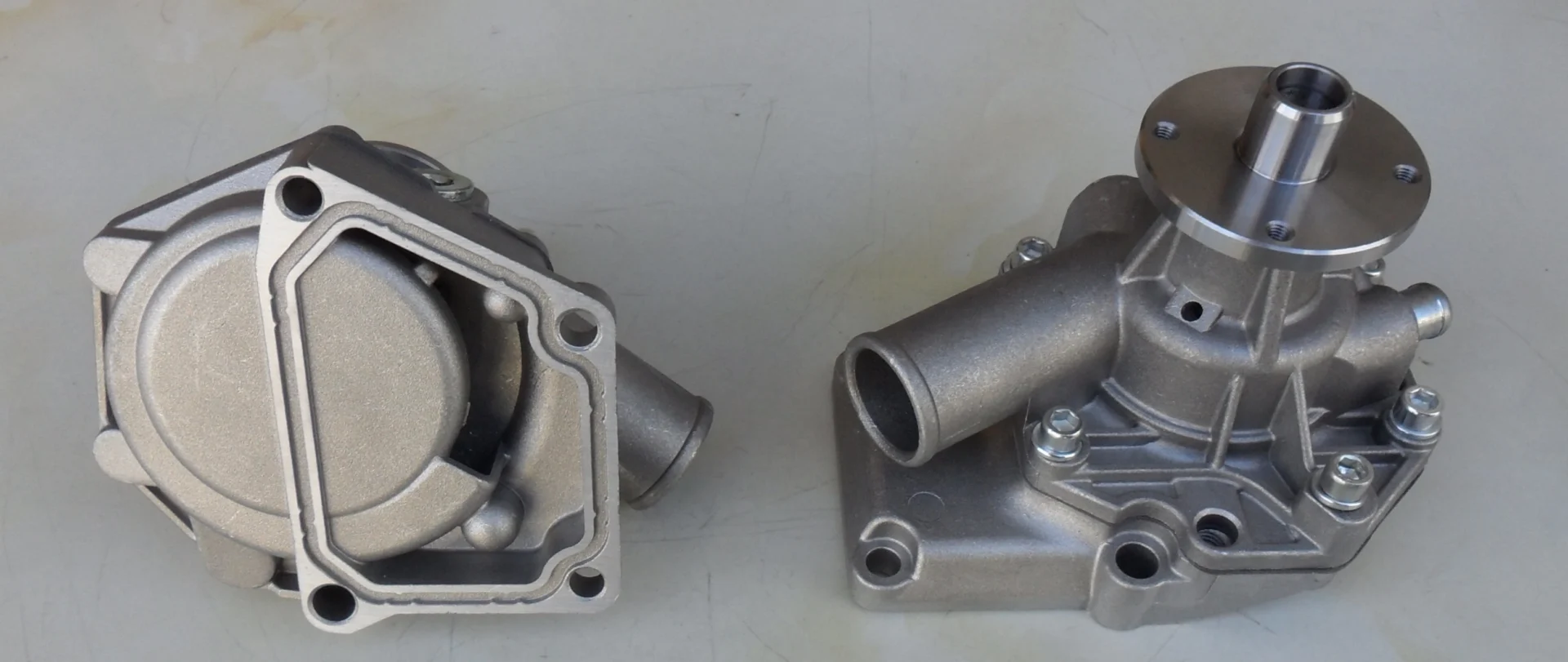

Hubei Cicada’s Commitment to Quality Engine Water Pump Parts

At Hubei Cicada, we understand how critical water pump reliability is for your equipment. Our commitment to quality ensures you get dependable parts that last.

Why Choose Hubei Cicada Water Pumps:

- Premium materials – high-grade metals and seals for durability

- Rigorous testing – every pump meets strict quality standards

- Industry compliance – meets or exceeds OEM specifications

- Comprehensive coverage – parts for diesel engines, generators, construction equipment

Our extensive product range includes:

- Water pumps for all major engine brands

- Complete cooling system components

- Radiators and intercoolers

- Engine rebuild kits and components

“Quality control and durable materials ensure our water pumps provide reliable service and customer satisfaction.”

Additionally, our technical support team helps you choose the right parts for your specific application. We serve customers worldwide with premium replacement parts for:

- Diesel engines

- Generator sets

- Construction machinery

- Agricultural equipment

Conclusion: Keep Your Engine Running Strong with Proper Water Pump Maintenance

Maintaining your engine water pump doesn’t require advanced mechanical skills. However, it does require consistency and attention to detail. By following the maintenance schedule and watching for warning signs, you can prevent expensive repairs and keep your engine running smoothly for years.

Remember these key maintenance points:

- Check coolant levels monthly

- Replace coolant every 2-3 years

- Inspect belts and tensions regularly

- Address leaks and noises immediately

- Use quality replacement parts

🔧 Need Quality Water Pump Parts?

Trust Hubei Cicada for premium engine components that last. Our water pumps meet industry standards and come with technical support.

Visit cicapaparts.com today to browse our complete selection of engine parts!

✓ Premium Quality Parts | ✓ Worldwide Shipping | ✓ Technical Support

Don’t wait for a breakdown to take action. Start your proper water pump maintenance routine today, and your engine will thank you with years of reliable service.